BIKAR Metals companies

Already in the 3rd generation, the trade with non-ferrous metals is our business. During this time, we have built up trusting partnerships with leading manufacturers, suppliers and plants around the world. In this way, we ensure the quality of our materials, but above all their availability. This close relationship with our partners enables us to deliver at any time, even in difficult economic conditions, and to guarantee you maximum security of supply.

Extensive stocks of goods in our high-bay warehouses and storage halls ensure that all common standard materials and shapes are available at short notice. For special materials, our purchasing team finds suitable suppliers and procures the required quantities and qualities.

With our own logistics company, BIKAR LOGISTICS we offer the optimal solution to make your delivery ready for your production safely and on time.

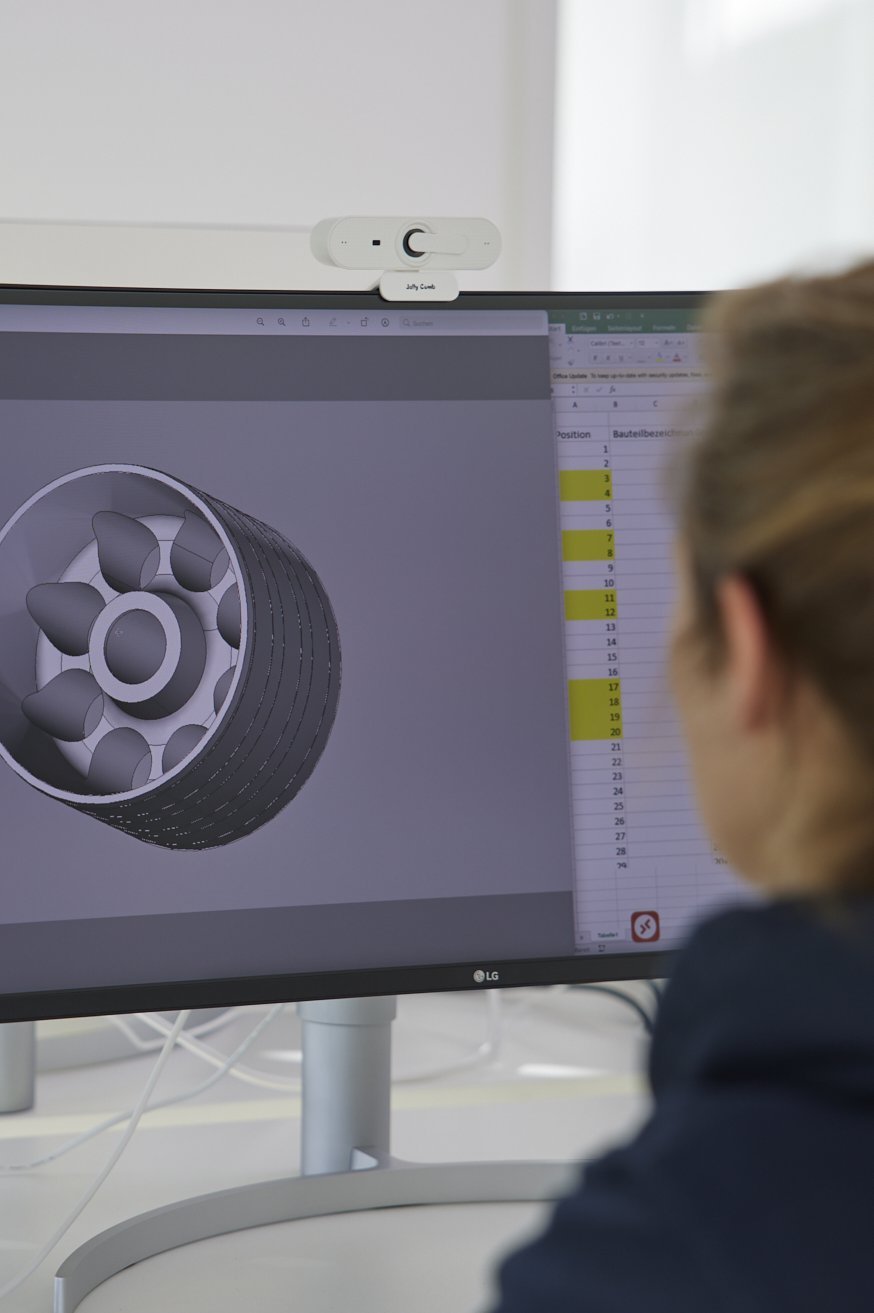

In our modern cutting centres, your semi-finished products are cut to the desired sizes and shapes. Depending on the type of products (drawn and pressed products, rolled sheets and cast material), we have designed special automation solutions and saws for the respective plants.

Due to the large quantities that are processed daily in our plants, it is possible to make optimal use of the starting material in order to generate as little waste as possible. This is good for the environment and your price.

With our BIKAR ZONE, we have succeeded for the first time in the world in automating the production of non-standardized blanks in the manner of series production and optimizing our production of semi-finished products and blanks made from rolled aluminium sheets economically and ecologically.

Our experienced sales team will work with you to develop the optimum strategy for your material supply. Whether fixed delivery dates within the framework of our own tours, framework agreements to secure attractive market prices in the long term or additional requirements at short notice - your contact persons are there for you.

It is also possible to set up a consignment warehouse: reduce your capital requirements, your inventory and your required storage space and still have direct access to your material

We are also happy to offer you our service in the field of finished parts. It is of particular importance to us that we do not face our customers from the machining industry as competitors. Therefore, we have decided not to carry out machining ourselves. Instead, we look for exactly the right machinists from our partner network for each request for drawing parts. This creates a win-win-win situation for all parties involved. Our customer receives his required finished part, our partner utilizes his machines and we have satisfied customers and partners.

Do you have an inquiry or would you like to become part of our network with your company? Contact us at zeichnungsteile@bikar.com.

The metal trade of the future is digital. At BIKAR, we internalized this early on and laid the foundation for further development by establishing a progressive IT department.

More than 50 experts develop individual solutions for our internal processes, but also for the connection of our suppliers and customers.

BIKAR counters high process costs with EDI for all business partners! Whether you use an outdated computer program or shy away from high investment costs - we provide expert advice at every step and support you in setting up an interface according to all current EDI standards.

Requirements are still typed in, sent, entered again, a quotation sent and processed. All this cost a lot of time and ties up resources. Given the high cost of labour and the increasing scarcity of skilled labour, this approach is no longer appropriate.

With an individual EDI interface, you can save yourself this work. Talk to us! At edi@bikar.com we will find the ideal solution together.